30+ years of mastering rotating equipment has taught us that true reliability isn’t built on quick fixes.

It’s built on deep expertise that spans every manufacturer and lifecycle stage so that you and your team get the best rotating equipment solution every time.

We create solutions to continuously improve reliability to help customers to achieve the lowest total cost to the client and the environment.

We are driven to ensure our customers’ success. Westpower is committed to achieving and sustaining outstanding results for all our stakeholders while ensuring safety is a priority for all initiatives.

From behind our desks to out in the field, we live our values every single day.

People

Our 100+ specialists become an extension of your team, offering deep technical knowledge with a genuine curiosity for your unique needs. We’re here to help develop your advantage, protect your critical operations, provide solutions that optimize reliability and lower your total cost of ownership.

Safety, Environment, Community

Safety and sustainability are more than policies, they are commitments embedded into every decision and action. Beyond our COR certification, we continuously identify risks, foster accountability, and improve our processes to protect people and the environment. By creating a culture where safety is a shared responsibility, we empower everyone to take ownership, ensuring we all contribute to a safer, more sustainable future.

Competence

Our knowledge and advanced capabilities allow us to diagnose equipment issues at the source and implement lasting improvements. Our reputation as a trusted industry partner is built on our ability to solve complex problems with precision, ensuring our clients operate safely, efficiently, and ahead of the competition.

Honesty & Forthrightness

We tell it like it is – no fluff, no pressure, just straightforward solutions built on real experience. We focus on what works best for you and benefits your bottom line. We build trust and long-term relationships by being direct about what works, what doesn’t, and execute on our promises.

Future Focus

Innovation drives our evolution. We nurture a forward-thinking mindset, encouraging our people to challenge the status quo and embrace change. By continuously investing in new technologies, refining our processes, and anticipating industry shifts, we empower our team and our customers to stay ahead. Our commitment to innovation isn’t just about keeping pace, it’s about leading the way and shaping the future.

Urgency

Downtime hits your bottom line. That’s why our field teams and repair centers promise rapid response times and preventative solutions to address immediate needs while preventing future failures.

Here’s what we mean when we say “we’re your rotating equipment partners for life.”

We start by fully understanding your equipment needs. Whether assessing new equipment or evaluating existing rotating assets, our experts identify ways to enhance reliability, reduce downtime, and lower costs. We collaborate with you to explore solutions that align with your goals for efficiency, sustainability, and safety to ensure the right fit without a sales push.

We identify the best solutions for your equipment needs or determine whether your equipment needs to be rerated, remanufactured, redesigned, or replaced (4Rs). If restoration or improvement is necessary, we apply in-house manufacturing and engineering enhancements to develop bespoke solutions. Westpower’s elite pump OEM partners or our in-house resources and rotating equipment specialist have the tools to offer you the most practical solution.

We put your solution to work by managing our supply chain, manufacturing, and inventory, ensuring smooth order fulfillment and installation. Throughout the equipment lifecycle, we provide continuous support – adapting to your changing needs by reassessing, refining, or redesigning solutions to maximize performance and longevity.

Every fall since 1995, we’ve brought our industry together for our Charity Pig Roast. Alongside live music, casino games, and specialty bars, we support CP Kids & Families’ Adapted Bike Program by donating and manufacturing custom parts that make cycling and outdoor life possible for children living with cerebral palsy.

More details coming soon

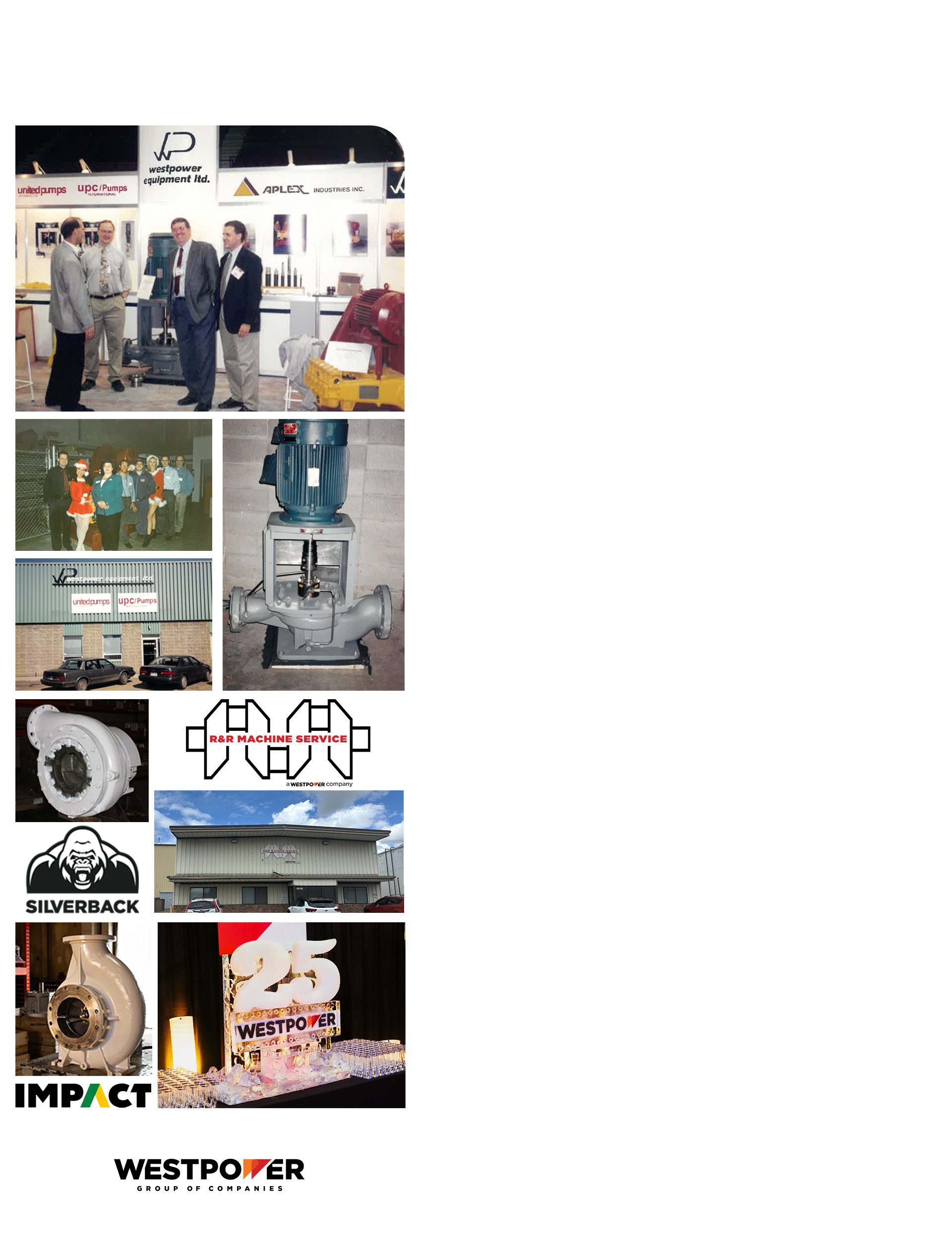

Founded as a CPC Pumps representative, Westpower grew from a small warehouse to a 9,000 sq. ft. facility by 1997, expanding its team, launching its first machine shop, developing pump packages, manufacturing custom pumps in 1999 that evolved into the MABRE product line, and hosted its first Pig Roast.

Expanded its Calgary facility to 18,000 sq. ft., launched its packaging division, established MABRE Pump Inc., earned its first “Supplier of Choice” award, acquired the Spartco repair facility in Edmonton, relocated its headquarters to a 30,000 sq. ft. facility. Westpower also created the inaugural API 610 Forum which evolved into the Calgary Pump Symposium – a biennial event that continues to raise hundreds of thousands of dollars towards post-secondary education, helping thousands of technical professionals within the local industry. Westpower also grew its Pig Roast into an industry event.

Westpower grew to 80+ employees, expanded into specialty HVOF coatings, won “Supplier of the Year” for the Northwest Redwater Upgrader Project, launched the frac pump plunger business that became IMPACT, and acquired an additional 20,000 sq. ft. facility for packaging and manufacturing.

Focused investment into the U.S. with sales offices in California and Denver, established field service and repair facility in Grande Prairie, strengthened our presence in the PADD IV U.S. region while acquiring R&R Machine Services Inc. in Salt Lake City.

In 2018, we celebrated our 25th anniversary, rebranded and launched the Silverback slurry pump line. We remained resilient as an essential service during the pandemic, closed our packaging division to partner with local packagers. Post pandemic, Westpower continued its strong growth, increasing market share in the pressure pumping market, engineered repair, and developed the Silverback suction pump. We also grew our facility footprint across North America by 40%.

Westpower strategically spun off its manufacturing and oilfield services into IMPACT Pump Solutions, now home to Silverback pumps, IMPACT expendables, and MABRE process pumps. The Calgary facility expanded to 34,000 sq. ft., with total group operations now spanning over 120,000 sq. ft. in Canada and in the U.S.

With a clear focus on Western Canada, Westpower is expanding its footprint to become the region’s leading distributor and service provider for rotating equipment across all industries. We’re developing new service facilities and advancing our solutions to meet the evolving needs of current and future clients.

The Westpower Group of Companies is now built for the future, strategically structured to drive long-term growth by aligning specialized expertise in manufacturing, distribution, repair, and service. We will continue to combine strong local and regional expertise with the ability to pursue global opportunities.

We offer meaningful work, hands-on experience, and a culture built on trust and technical excellence.