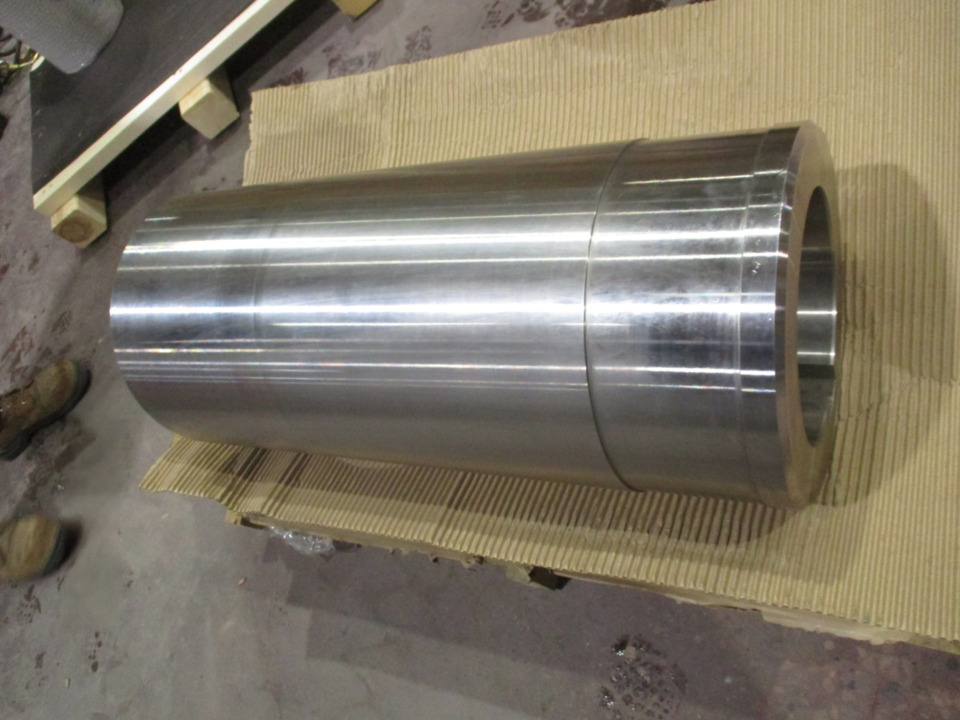

Challenge: Production of a Large Shaft Coupling

A large electrical utility in the Middle East required a large shaft coupling for an Allis-Chalmers 108-78 WCAR VS1 cooling water pump. The part presented complexities due to its oversized design and the specific keyway dimensions (over 25 inches in length), which made it difficult to fabricate. The client needed a trusted supplier with engineering expertise, supplier network, and manufacturing capabilities to deliver a cost-effective, high-quality solution within the project timeline.

Solution & Results: Leveraging Westpower’s Expertise and Global Supply Chain

Westpower, with its extensive supplier network and in-depth manufacturing capabilities, was selected as the preferred partner for this complex task. Our collaboration involved multiple teams, including the Edmonton Repair Shop, Engineered Repair team, Non-OEM parts teams, and our vendor management team located internationally.

Despite the challenges associated with producing such a large and intricate part, Westpower’s expertise in managing supply chain logistics played a crucial role in the successful execution of the project. By leveraging our global supply chain, we were able to source components from trusted vendors and bring the part to our Canada shop for finishing and quality control.

The outcome was a high-quality shaft coupling fabricated to the required specifications, delivered on time, and within the agreed budget. The project not only reinforced the client’s confidence in Westpower’s ability to handle complex components but also highlighted the value of Westpower’s global supply chain network and parts manufacturing expertise in the utilities sector.