A North American refinery faced a critical operational challenge when their previous vendor suffered a cybersecurity breach, resulting in the loss of all spare part design data. Without access to technical drawings, fabrication specifications, or CAD models, the client had no way to replace essential pump components consumed in routine maintenance without recreating the design and fabrication drawing.

Recognizing the urgency, the client turned to Westpower and R&R for a comprehensive reverse engineering solution to recover their lost design repository and ensure long-term parts availability.

Westpower’s Solution: Expert 3D Scanning & CAD Reconstruction

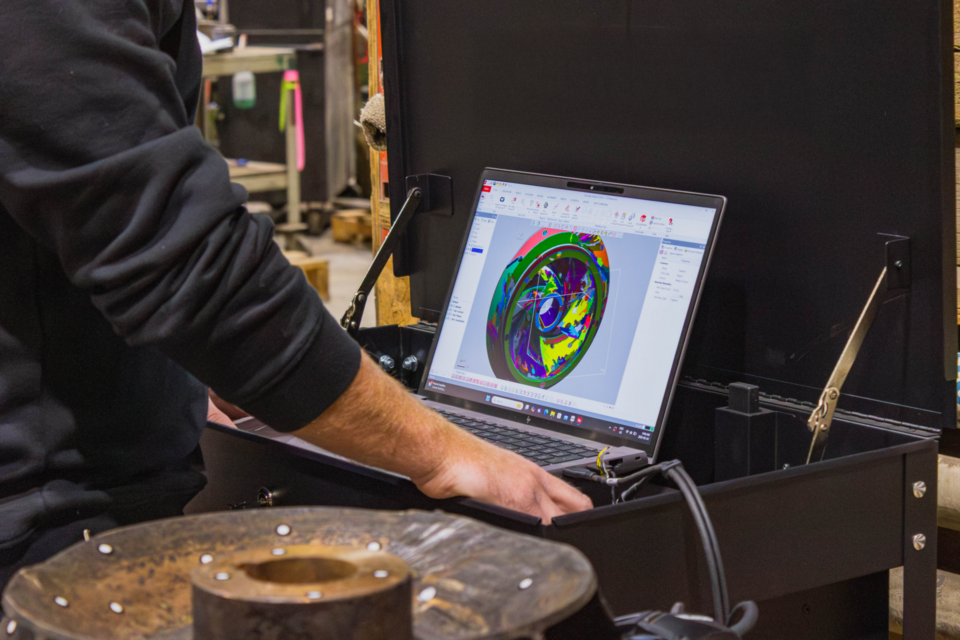

Westpower’s on-site metrology and 3D scanning specialists deployed a part recreation strategy, including:

- High-Precision 3D Scanning & Part Metrology – Capturing detailed part geometry for accurate digital reconstruction

- CAD Modeling & Procurement-Ready Drawings – Recreating lost designs with meticulous attention to engineering tolerances

- Ongoing Data Collection & Expansion – Project scope grew from 502 parts to 1,650 parts, reflecting the client’s increasing trust in Westpower’s expertise.

Project Outcomes: Reliable Spare Part Source & Long-Term Security

As a result of Westpower and R&R’s expertise, the client successfully recovered critical spare part designs, ensuring uninterrupted refinery operations and long-term part supply stability. By modifying several part designs, we helped improve manufacturability while also establishing a secure digital design repository to safeguard against potential data loss. This project not only restored essential part procurement capabilities but also strengthened the client’s trust in Westpower, leading to several hundred thousand dollars in part orders and reinforcing our role as a reliable engineering partner.