Challenge: Cavitation, Vibration, and Shaft Failures on a Crude Charge Pump

A major Salt Lake City refinery needed to upgrade their crude charge pump after years of running significantly off the best efficiency point (BEP). Issues experienced by this pump included cavitation and high vibration levels that led to pre-mature bearing failure, internal erosion, decreased equipment reliability, and lower efficiency.

Replacing the charge pump with a new fit-for-purpose or existing OEM solution was not feasible due to a long lead time of over 1-year. Additionally, new pump installation, grouting, piping, planning, engineering, design, installation and commissioning would require the Client to undergo a lengthy and costly management of change process (MOC), on an already failing pump. Years of reliability issues including a broken shaft due to excessive vibration, finally forced this Client, one of the world’s leading oil companies, to take action to mitigate safety concerns, unplanned downtime and the potential loss of production.

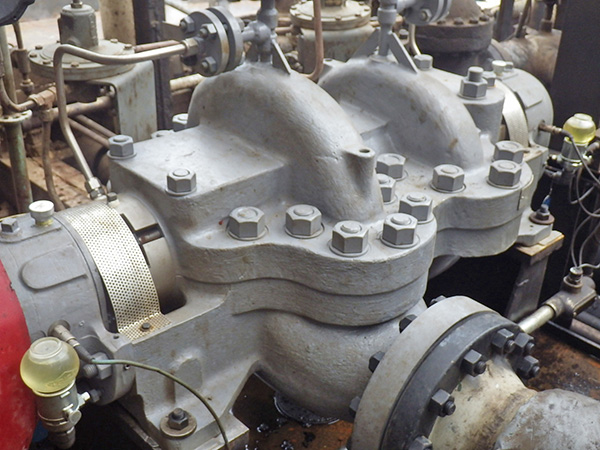

Westpower’s Custom Hydraulic Re-Rate Solution for Crude Charge Pump

Westpower created a custom engineered solution, as the existing OEM pump specifications would not satisfy this project’s unique scope requirements. The solution included Westpower completing the hydraulic design engineering and providing R&R with the guidance to modify the volutes and source the custom designed impellers. A new casing material was also selected to maximize efficiency. Downtime was significantly reduced compared to installing a new pump as a revision to the existing pump didn’t warrant the Client to go through their lengthy and costly MOC process. Now installed, the crude charge pumps are operating flawlessly, and this Client was able to significantly reduce their vibration levels, in turn also reducing their operating costs while significantly improving their overall performance and reliability.

Results: Increased Efficiency and Enhanced Pump Reliability

The successful outcome of this initiative was the result of Westpower’s engineering and technical expertise, that delivered a cost-effective and reliable solution within the bounds of our client’s project scope constraints. Ultimately, by optimizing the pump curve, Westpower produced a pump solution that worked for the Client’s operating conditions and requirements rather than the Client having to adapt to a rigid pump specification and accept inefficient operations.