Based on client needs around design, cost, delivery, and quality, Westpower provides the optimal solution, offering OEM, non-OEM, or upgraded parts to ensure the best fit for performance and reliability.

Westpower understands the rigorous demands of industrial, engineered, and process pump applications. Pump reliability is critical to operational efficiency, from oil & gas and petrochemical processing to power generation and water treatment. While OEM parts are often the default choice, high-quality non-OEM pump parts offer a cost-effective and reliable alternative to meet or exceed OEM pump part specifications. Non-OEM parts are also essential for aging or legacy equipment no longer supported by OEMs, ensuring continued operation without costly system overhauls or replacements. Westpower enhances legacy pumps with fit-for-purpose, engineered non-OEM parts that optimize performance and often exceed original pump’s performance.

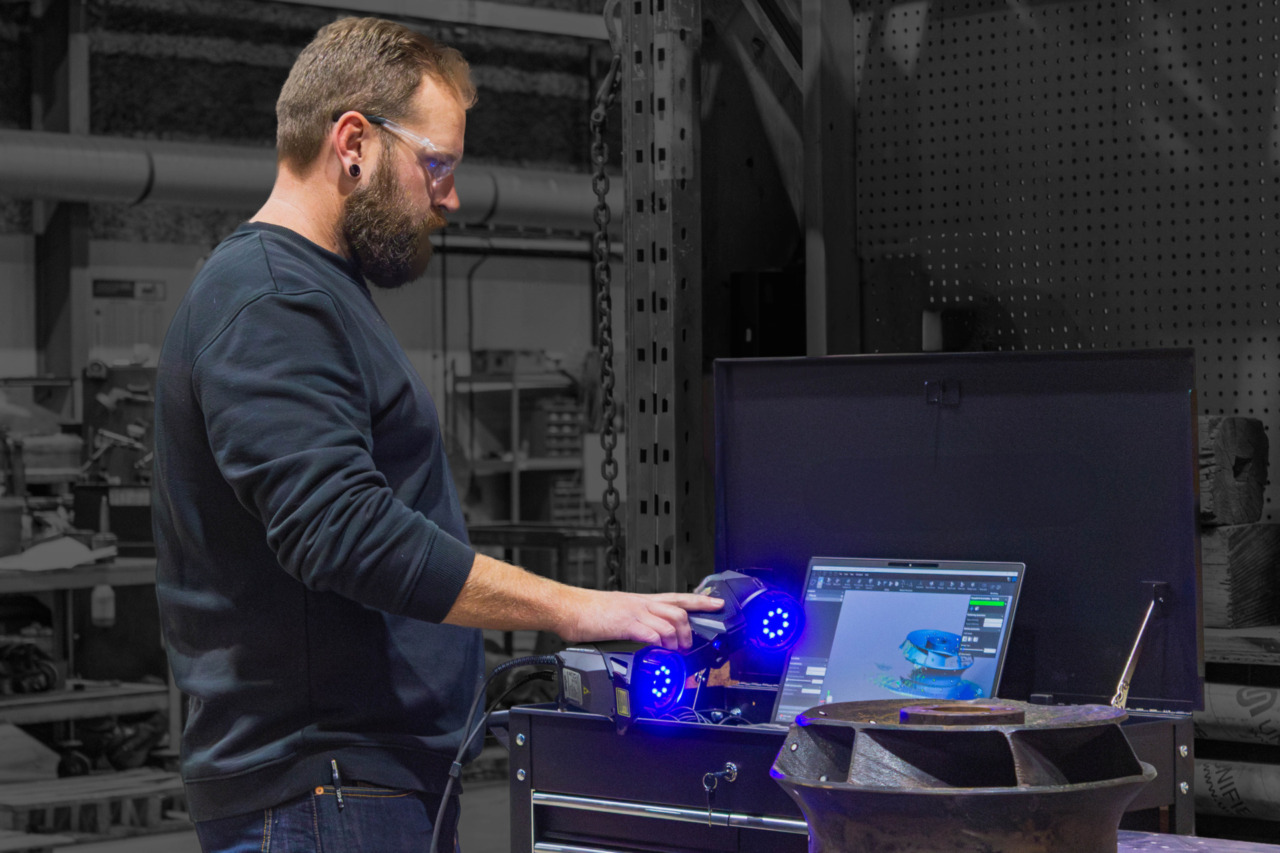

We evaluate your specific needs, performance requirements, and application conditions to deliver non-OEM parts that balance cost, lead time, design precision, and quality. Our engineering expertise helps maintain or enhance metallurgy and design specifications for demanding applications, including high-pressure, high-temperature, and corrosive environments. When OEM parts are unavailable or have long lead times, we provide high-quality, fit-for-purpose, non-OEM alternatives to keep your operations running efficiently.

Reduce maintenance and replacement costs while maintaining top-tier performance.

Faster availability compared to OEM parts, minimizing downtime in critical operations.

Designed exactly for your unique operating and industry conditions.

Engineered and machined to exact tolerances for seamless integration with existing pump systems.

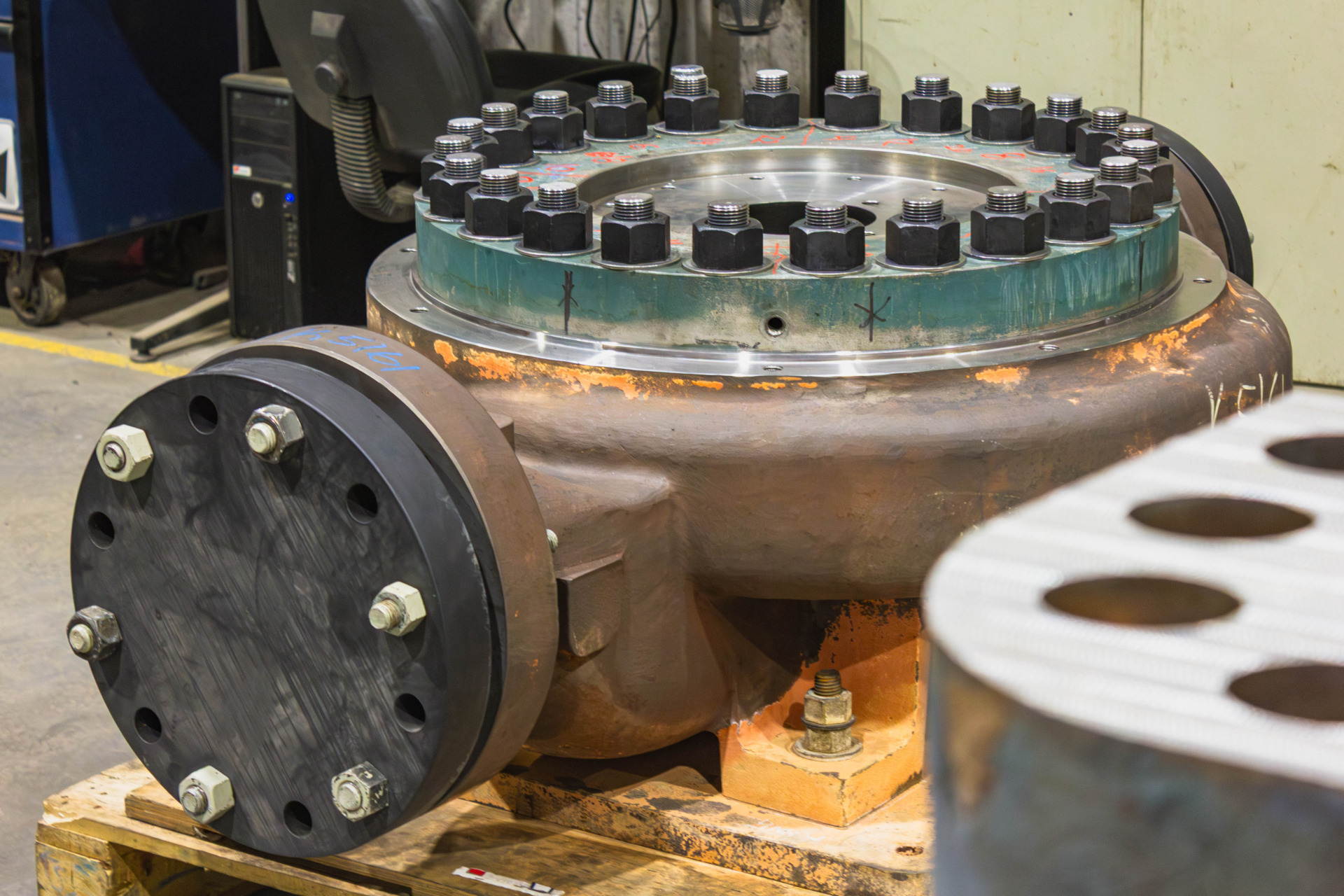

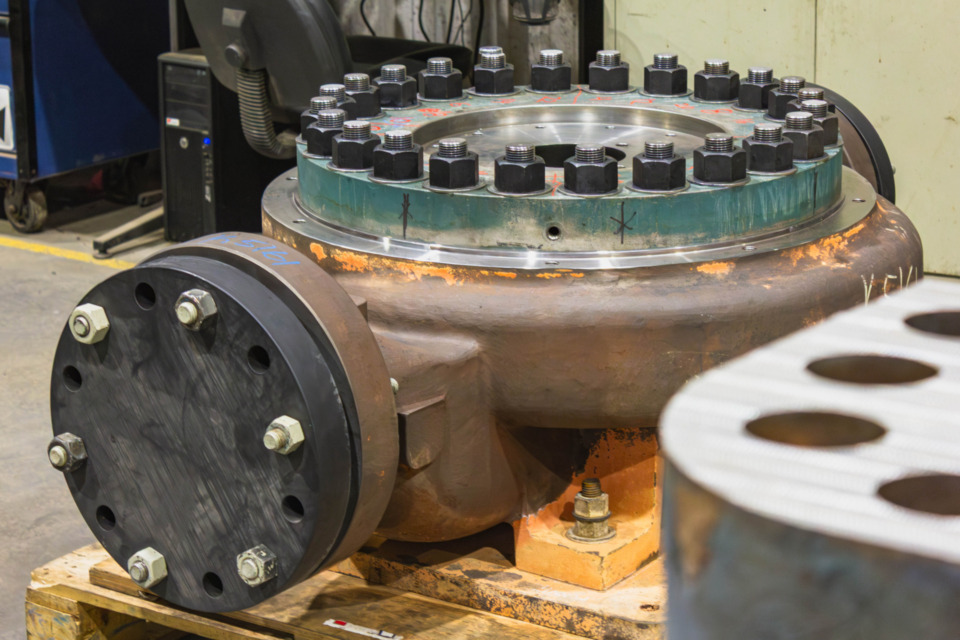

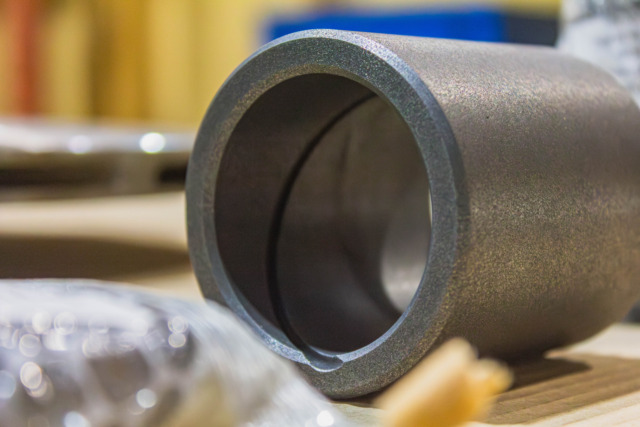

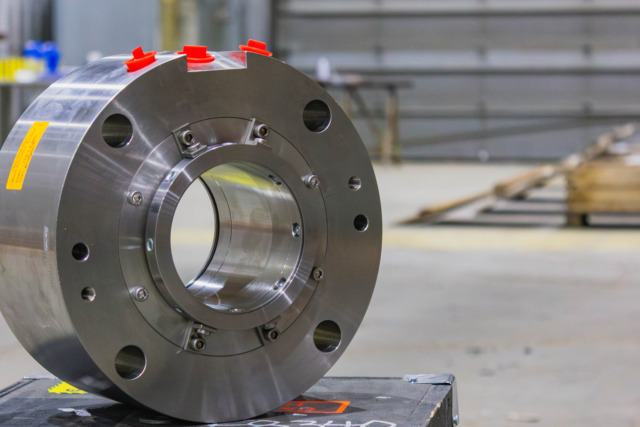

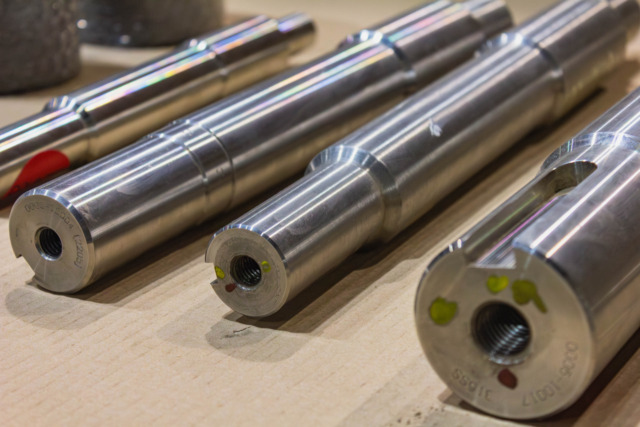

Westpower supplies a full range of non-OEM replacement parts tailored to industrial, process, and engineered pump applications. Whether you’re looking to replace a single component or overhaul an entire pump system, our non-OEM parts deliver the quality, longevity, and cost-efficiency your operations demand.

Designed to reduce friction and extend component life in high-load applications.

Precision engineered for leak prevention in any operating environment.

Optimized hydraulic design and available in various materials.

Precision manufactured with wide material availability and engineered surface coatings.

Precision-machined for structural integrity and superior hydraulic performance.

Need something specific or obscure? We’ll design and manufacture it for you. Contact us!

Selecting the right non-OEM part is crucial to maintaining system integrity and reliability. Westpower’s engineering and applications teams collaborate with customers to analyze pump performance, diagnose wear patterns, and recommend the optimal components for their specific needs. We carefully select and source materials to ensure each part is built to outperform within any operating environment. Our quality control processes and metallurgical expertise ensure that every component meets or exceeds industry and OEM standards, providing dependable performance in demanding environments.

The reliability of non-OEM parts depends on several factors, including the manufacturer’s expertise and adherence to design specifications. While OEM parts are built to strict standards, ensuring consistent fit, performance, and reliability, non-OEM parts can vary. Some non-OEM parts may offer cost-effective alternatives or even improved performance, but they may come with risks related to material quality, tolerances, and long-term durability.

By working with an experienced manufacturer like Westpower, you can mitigate these risks, as we apply deep engineering knowledge to ensure that both OEM and non-OEM parts meet high reliability, performance, and quality standards. The key decision ultimately comes down to balancing quality, cost, and delivery while evaluating the long-term benefits for your pump system’s performance.

Non-OEM parts can often reduce costs through lower initial prices, faster delivery, and tailored designs. While they are often more readily available, some custom non-OEM parts, engineered with enhanced materials for specific applications, may not always be cheaper. However, they can still provide long-term savings by improving performance and extending part lifespan, ultimately lowering your total cost of ownership.

Absolutely. Our non-OEM parts are designed for exact compatibility with a wide range of industrial, engineered, and process pumps. Our team of experts ensures that every component is precision-matched to your pump’s specifications, providing a reliable and efficient replacement solution.

We supply non-OEM replacement parts for a wide range of pump brands and models, including centrifugal, reciprocating, and positive displacement pumps used in industrial, energy, process applications and more.

Non-OEM parts are a smart choice in many scenarios – we’ll help you determine where they make the most sense for your goals.