Based on client needs around design, cost, delivery, and quality, Westpower provides the optimal solution, offering OEM, non-OEM, or upgraded parts to ensure the best fit for performance and reliability.

Westpower recognizes the critical importance of maintaining and enhancing pump performance in process applications. Our upgraded and engineered pump components are designed to optimize efficiency, extend equipment lifespan, and reduce operational costs.

Upgrading pump components with engineered parts enhances system reliability, efficiency, and reducing unplanned downtime. Standard OEM designs may not always be optimized for demanding conditions, but our engineered solutions deliver improved reliability and performance tailored to your specific needs. By integrating these advanced parts, you extend equipment life and reduce the total cost of ownership, ensuring optimal performance across your operations.

Westpower’s upgraded pump parts reduce the risk of failures and leaks, protecting personnel and ensuring a safer working environment by maintaining reliable, secure pump operation.

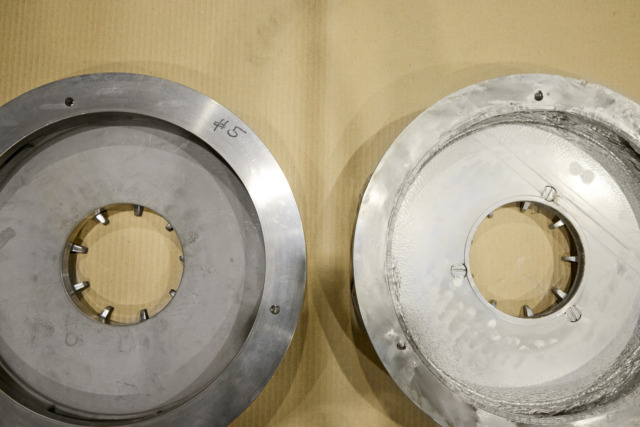

Our upgraded parts feature advanced materials, engineered coating technology, and design modifications to withstand any operating environment. This extends component lifespan and minimizes premature failures.

Our engineered parts are designed to last longer and perform better than standard components, reducing maintenance costs, unplanned downtime, and the need for frequent replacements. Improved efficiency also results in lower operational expenses.

Unlike standard OEM replacements, our upgraded pump parts can be custom-tailored to address specific process challenges. Whether it’s high-temperature applications, chemical resistance, or increased wear protection, we design solutions that align with your industry’s unique needs.

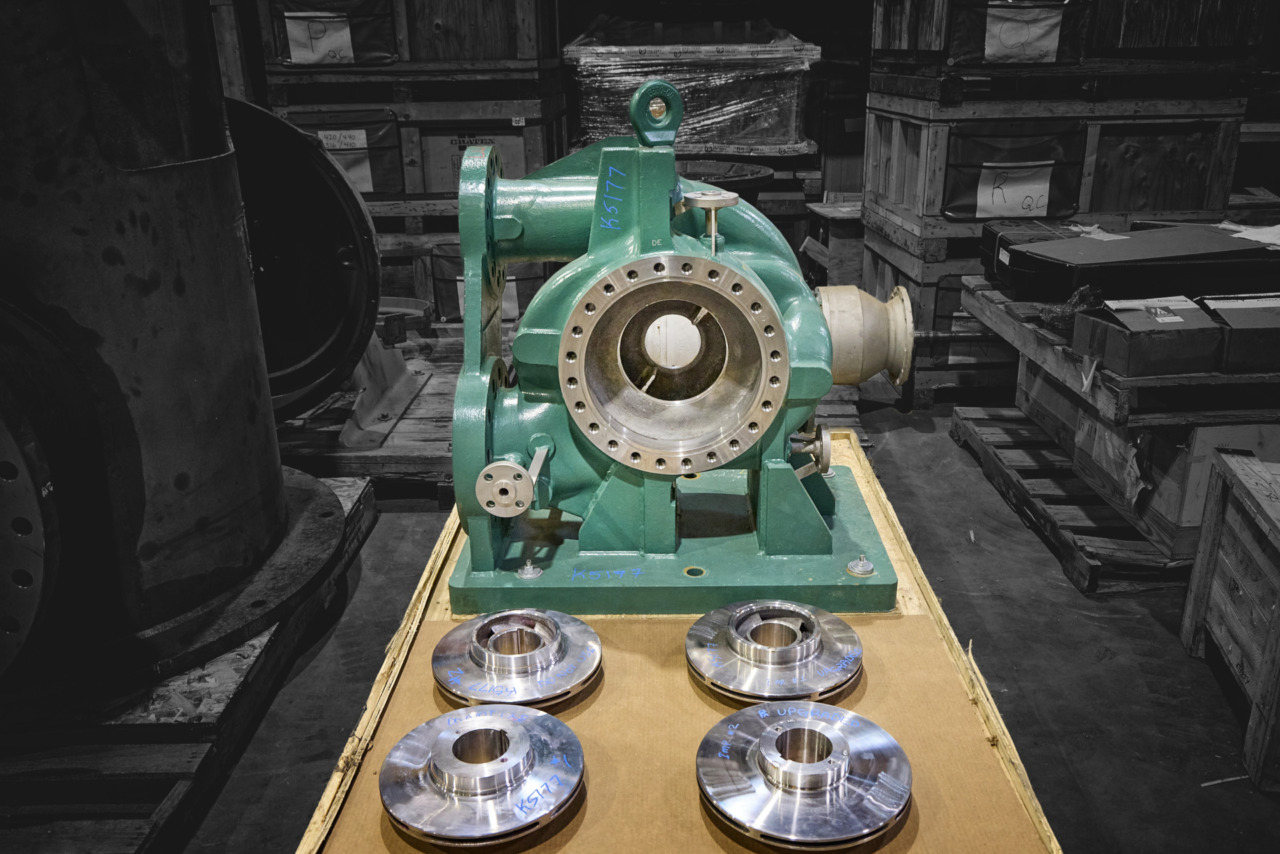

Westpower offers a full range of upgraded and engineered pump parts tailored to process applications. We work closely with customers to understand their operational needs, ensuring each part is custom-designed for optimal performance. From material selection to manufacturing, we ensure every component is designed to withstand its unique operating conditions while optimizing for the lowest total cost of ownership.

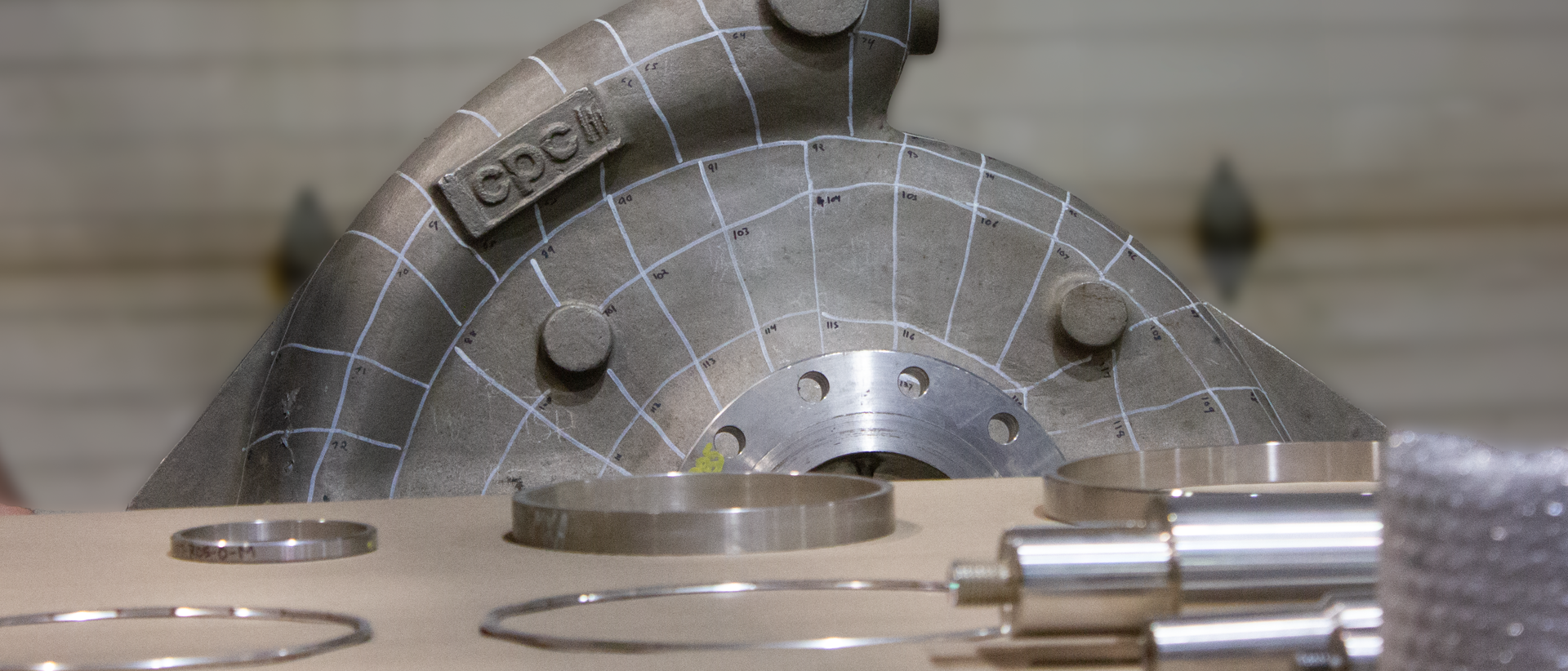

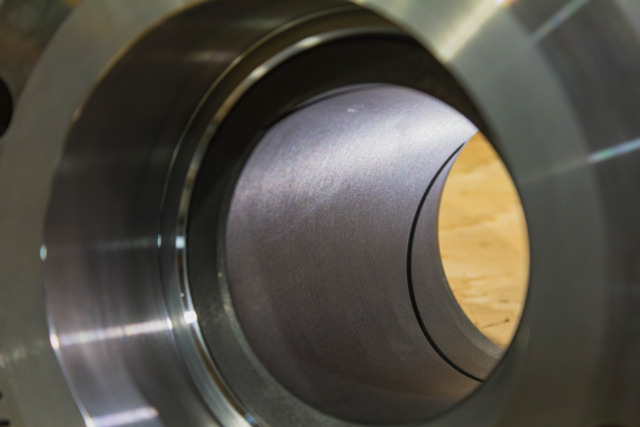

Redesigned for improved hydraulic performance and reduced cavitation.

Engineered to increase wear resistance and extend component lifespan in harsh conditions.

Applied to prevent corrosion and abrasion, ensuring long-term reliability.

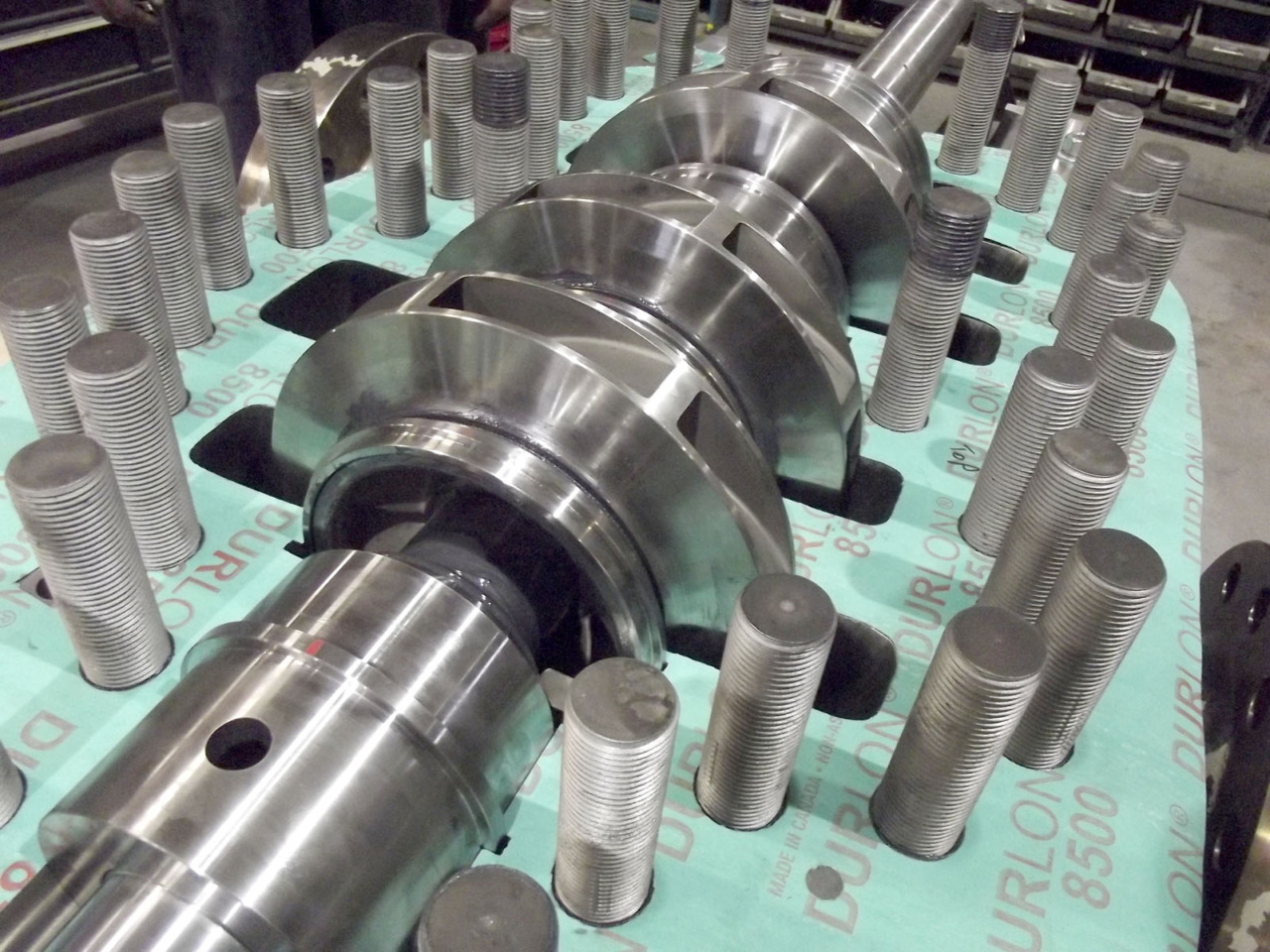

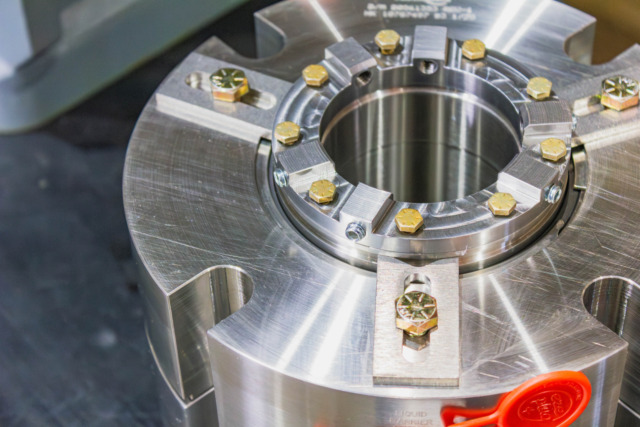

Built to withstand high pressure and temperature while preventing leaks.

Designed for higher load capacity and reduced vibration in demanding applications.

Tailored solutions for unique applications. Contact us!

Westpower’s expertise goes beyond supplying parts: we engineer lasting solutions. Our team of pump and rotating equipment specialists includes engineers, application experts, millwrights, metallurgists, machinists, and other highly skilled tradespeople who collaborate to conceptualize, design, and manufacture upgraded pump components tailored to your specific operational requirements.

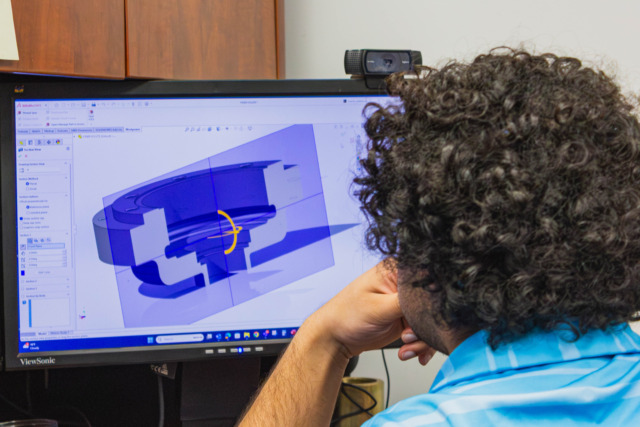

Whether you need enhanced wear resistance, improved hydraulic performance, or corrosion-resistant materials, our experts evaluate your system’s unique demands to develop precision-engineered parts that maximize reliability and efficiency. We use advanced material science and computational modelling to design components that meet and often exceed standard OEM designs. We employ advanced manufacturing techniques, including 3D printing, laser welding, HVOF coatings, precision machining, and additive manufacturing, among others.

From concept to final quality inspection, we ensure every upgraded part is optimized for fit, function, and longevity, reducing downtime, extending equipment life, and delivering cost savings.

We design and upgrade critical pump components to outperform standard parts in your toughest applications.