With over 30 years of experience, Westpower offers a lifecycle-focused approach to pump installation, start-up, and commissioning. From equipment selection to post-commissioning support, we integrate seamlessly with end-users, site owners, integrators and EPCs to optimize system performance. In addition to major rotating equipment, we also expertly assess auxiliary system elements like lubrication, piping, and foundations to ensure everything is properly configured before start-up.Our approach minimizes downtime and enhances your pump system’s long-term reliability and performance.

Westpower’s pump installation services are designed to achieve optimal alignment, proper mounting, and seamless integration with your system, meeting and exceeding OEM factory requirements and API 686 guidelines. Our technicians use proven techniques to minimize vibration, reduce wear, and extend the life of your equipment. Whether it’s a general industrial or a high-energy API pump, we handle all aspects of installation, from mechanical assembly, lubrication, piping alignment, dry and wet commissioning checks and more, ensuring everything meets precise operational specifications.

Avoid costly future maintenance by leveraging Westpower’s expertise to ensure the proper alignment of equipment from the start.

Beyond the rotating equipment, Westpower’s machinery specialists ensure that all auxiliary systems are installed and commissioned for start-up.

Reduce the destructive impact of vibration with Westpower’s expert installation practices that reduce wear and extend the lifespan of your pump.

Westpower’s installation methods and trained specialists follow our comprehensive procedures to ensure your system begins its life operating at its peak performance.

Our process-driven installation reduces the risk of unexpected failures, safeguarding against costly troubleshooting or unplanned downtime during or after start-up.

Westpower’s team of technicians, engineers, and millwrights execute every detail of the installation for optimal, long-term performance.

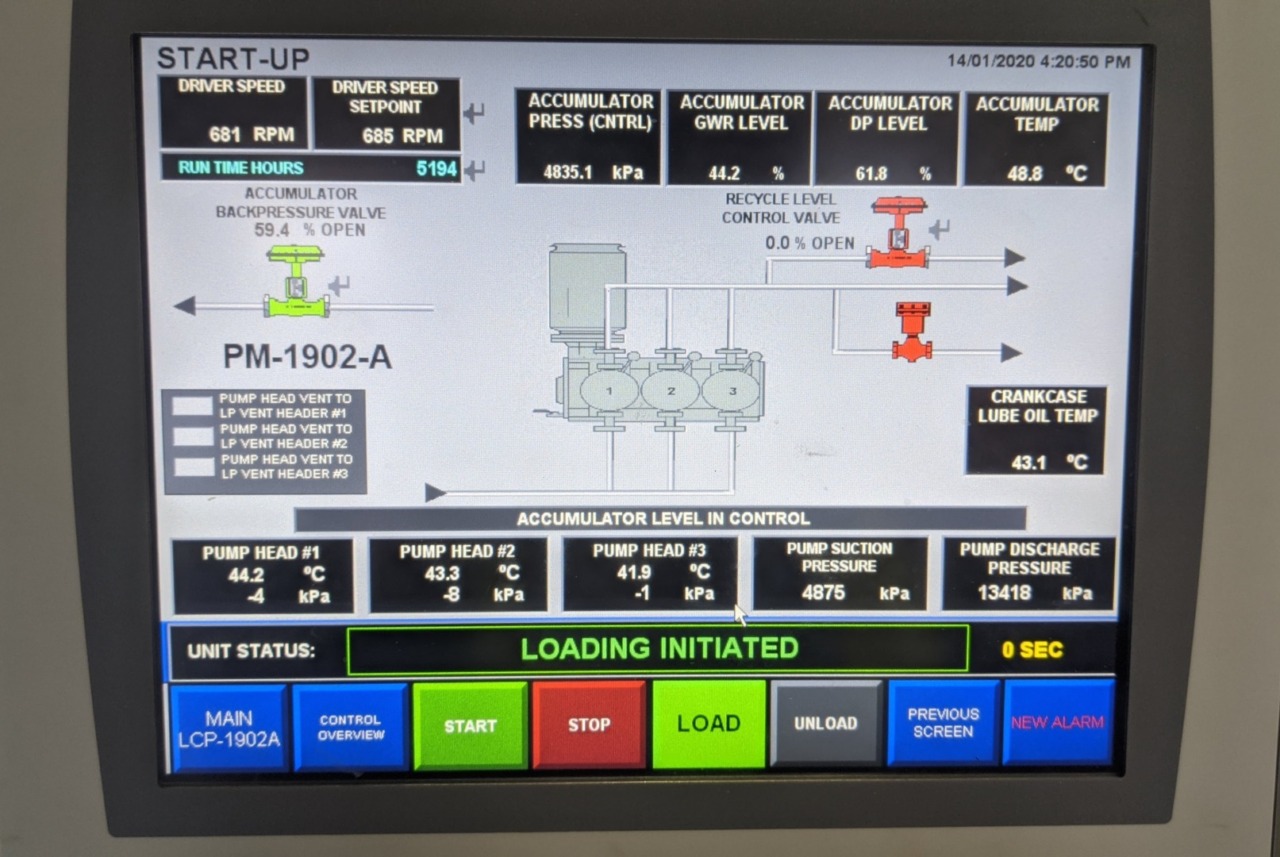

Our commissioning services include a full range of testing and baseline performance verification data to ensure your pump system operates within its design parameters. Westpower technicians monitor every aspect of your system, including pressure, flow and auxiliary system checks. We collaborate closely with site owners, EPCs, integrators and operators to optimize and prepare your system for seamless long-term operation.

Westpower’s comprehensive performance testing confirms that all system components meet required standards, including pressure and flow rates.

We verify that every aspect of the stabilized system performs exactly as intended, eliminating inefficiencies and preventing underperformance from affecting your operations.

Our commissioning team collaborates with you to fine-tune system settings, optimizing your system.

Our experts identify potential problems early during commissioning, proactively preventing costly downtime and repairs by addressing issues before they escalate.

Our experience with commissioning can help you achieve long-term, reliable performance, laying the foundation for continuous operation without unexpected failures.

All of Westpower’s technical resources support the commissioning team to ensure your system will perform optimally for years to come.

Start-up is a critical phase where the pump and associated systems are brought online for the first time. Our team conducts thorough assessments to integrate systems smoothly, from piping connections to auxiliary equipment. We perform essential pre-start checks to identify any issues before powering up the system, making sure all components, including lubrication and cooling systems, are properly configured for optimal operation.

Our meticulous start-up process sets the stage for efficient, trouble-free operation right from the beginning, minimizing the risk of issues during start-up.

Our team conducts pre-start diagnostics to confirm all components are functioning correctly before activation, preventing system failures and downtime at start-up.

Westpower’s careful management of the initial system start-up prevents equipment damage, safeguarding your assets and maximizing their lifespan.

We’ll collaborate closely with you to find installation and commissioning solutions for your equipment and site requirements.