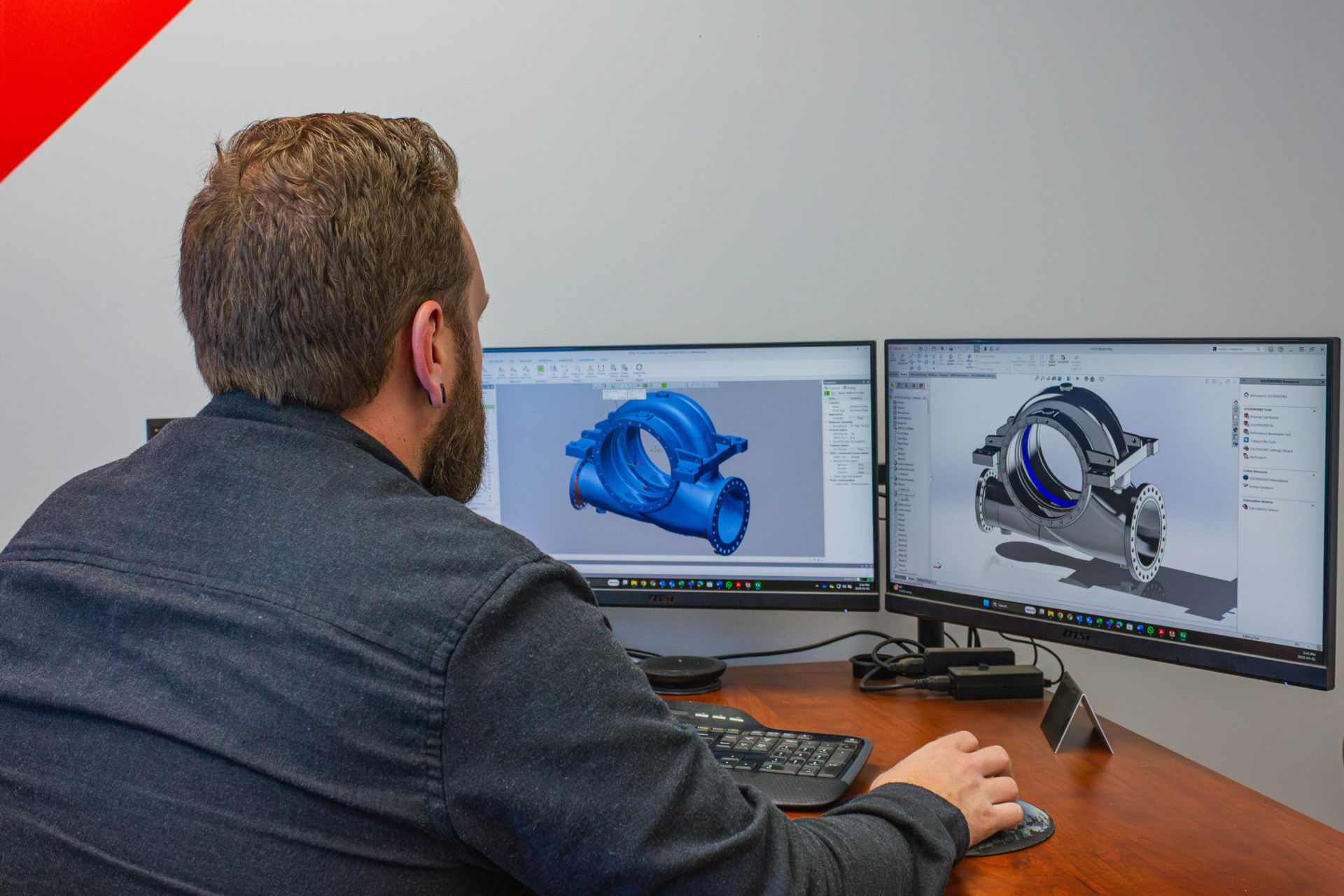

Real-world engineering,

grounded in pump expertise

At Westpower, engineering isn’t a department – it’s the foundation of how we deliver smarter, more reliable pump solutions across the full equipment lifecycle. Our team of over 20 engineers brings deep expertise in mechanical, hydraulic, metallurgical, and applications engineering, allowing us to solve complex challenges at every stage of your equipment’s operation. With decades of combined experience in pump systems, field operations, and new equipment design, we understand not just the pump but how it integrates into your broader process.

Whether planning new equipment, troubleshooting field performance, or engineering upgrades for legacy systems, Westpower’s engineering team delivers practical, technically sound solutions that protect your investment and support your long-term operations.

Applications Engineering

Westpower’s Applications Engineering team ensures that every pump we select, specify, or upgrade is precisely matched to your operating conditions and system needs. We understand the nuances of various pump types – whether from OEMs we represent or other major brands – and how each must perform within your unique process environment. Our team works closely with customers to assess duty conditions, fluid characteristics, system layouts, and site-specific constraints to recommend the best-fit solutions. By considering the full system impact, we help optimize pump performance, minimize energy consumption, and extend equipment life.

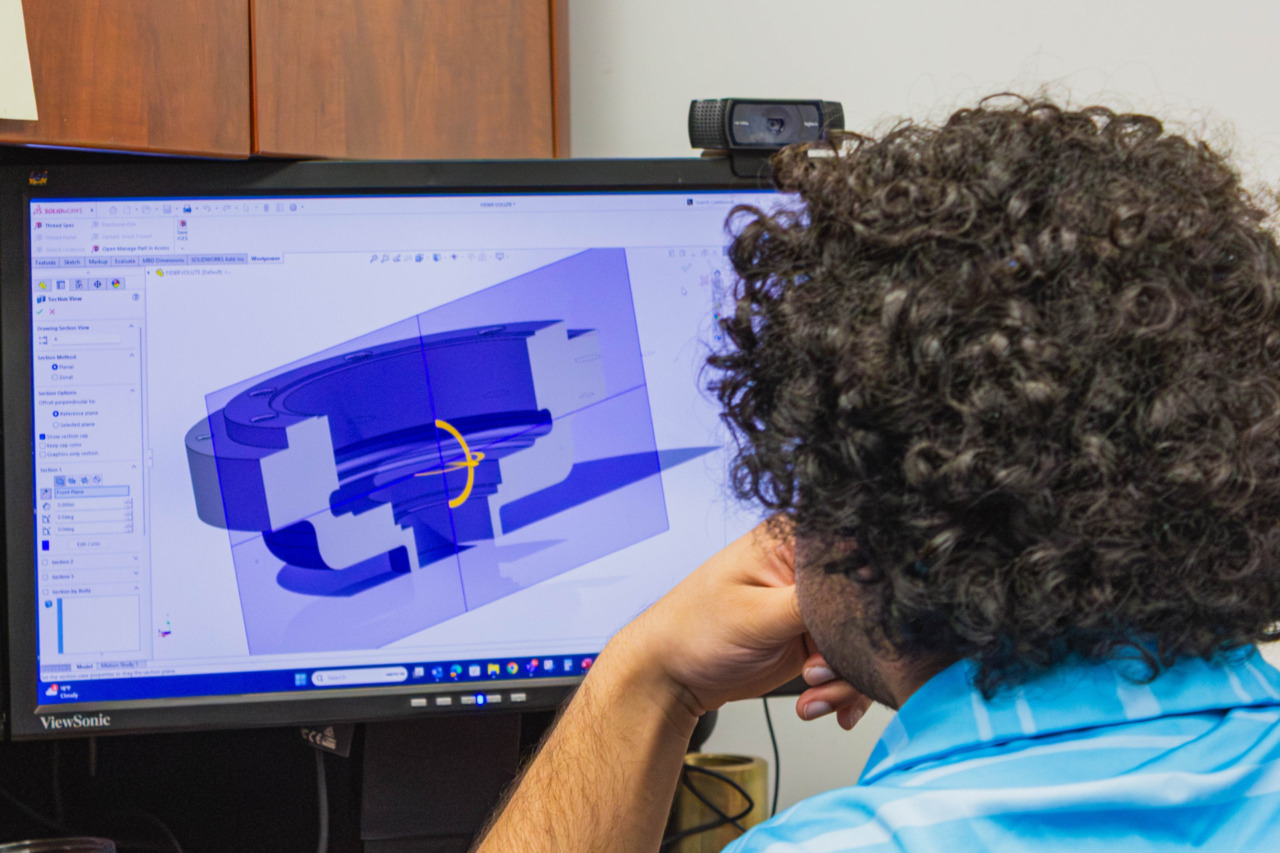

Hydraulic Design & Engineering

Westpower’s Hydraulic Engineering team specializes in selecting and modifying pumps to ensure the right fit for your specific application. Whether designing new hydraulics, adapting existing pumps for different service conditions, or performing re-rates, we apply decades of pump and system experience to deliver reliable, performance-driven solutions. Our expertise ensures that pumps meet the required flow, head, and system conditions while minimizing wear, improving uptime, and supporting long-term equipment health. A deep understanding of both OEM standards and real-world process requirements backs every hydraulic recommendation.

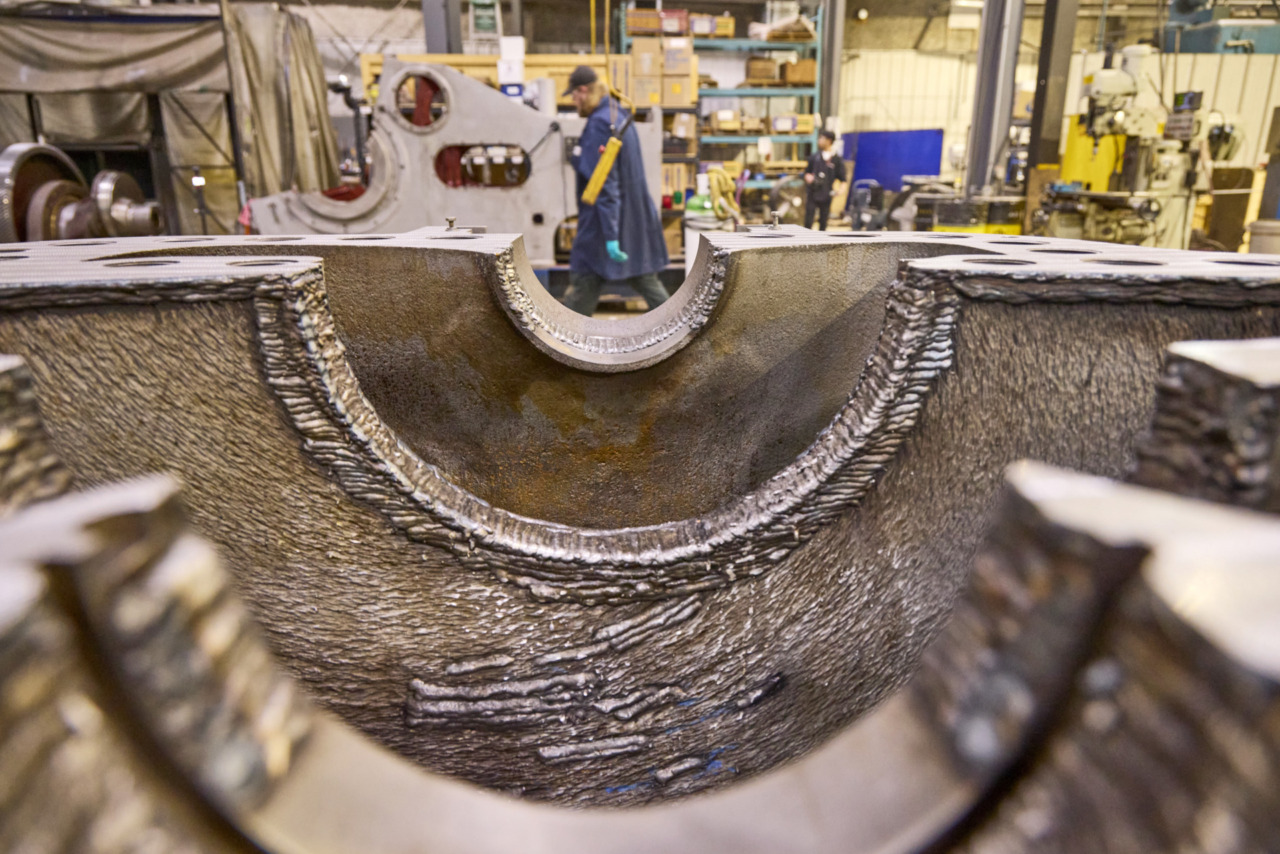

Metallurigical Engineering

Material selection is critical to pump performance, especially in challenging or corrosive environments. Westpower’s Metallurgical Engineering expertise ensures that the materials used in your equipment are suited to your fluid, temperature, pressure, and operational demands. Our team evaluates wear patterns, corrosion resistance, and material failures to recommend improvements that extend component life and reduce maintenance frequency. From upgrading metallurgy on critical parts to supporting engineered repairs, we combine laboratory knowledge with field insights to deliver more durable, reliable solutions.

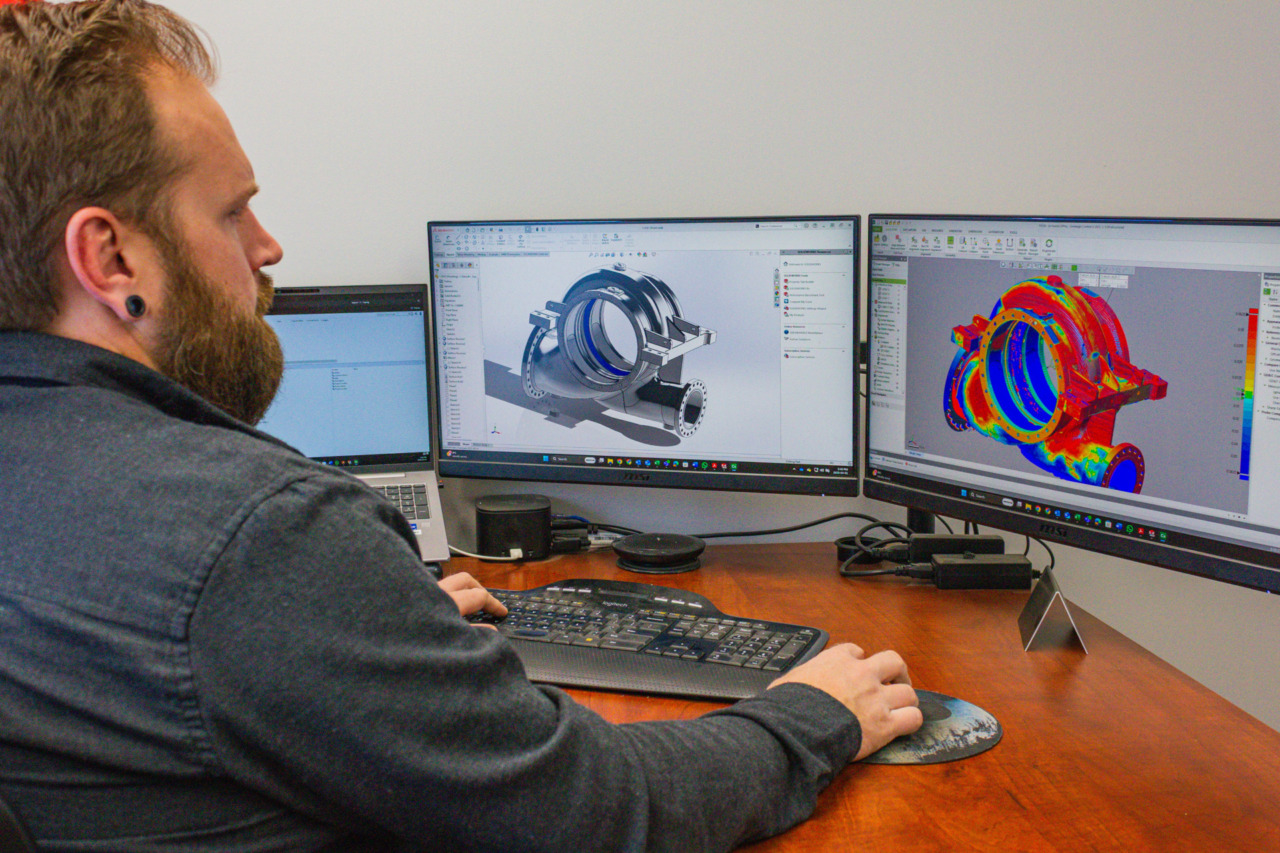

Mechanical Engineering

Our Mechanical Engineering team brings detailed technical expertise to the design, evaluation, and upgrade of pump components and assemblies. With decades of combined pump-specific experience, we analyze stresses, materials, and tolerances to ensure mechanical integrity under real-world operating conditions. Whether designing replacement parts, upgrading pump internals, or troubleshooting mechanical failures, Westpower’s engineers focus on extending equipment life, improving maintainability, and reducing long-term repair costs. Our deep understanding of OEM standards, paired with our field experience, ensures every solution is both practical and performance driven.

Suggested Services

Engineering expertise, built for real-world performance.

Let’s create solutions that protect your equipment, improve reliability, and lower your total cost of ownership.