On a facility wide basis has anyone optimized your lubricant selections and inventory?

Westpower offers a lubrication ASSESS program that will support your goal to extend the life of your capital assets to their ultimate design potential and bring you the best return for your capital investment. Our program is modular and can be implemented in stages depending on your resources availability.

The Westpower Offer

Our team provides you with generic and specific lubricant recommendations, once we receive a comprehensive list of your equipment with the following information:

- Equipment type

- Equipment OEM

- Equipment OEM Model

- Equipment serial number

- Actual Lubrication: lubricants and frequency

- Operating conditions:

- Wet or dry

- With or without dust

- Temperatures: ambient and equipment

- Shaft speed

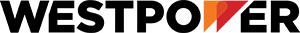

With the above information, we will ASSESS if it is the right lubricant at the right place and recommend the best lubricant.

Then we RATIONALISE the list of lubricants in use and streamline it. Generally operations carry many different hydraulic oil, gear oil and grease grades and brands when they need only one of each. This helps avoid mixing lubricants and using them in the wrong equipment.

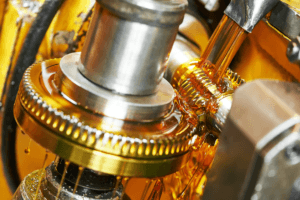

We assist with preventive maintenance to help eliminate costly unplanned stoppages. We use a credible third party oil analysis lab to do two things:

-

- Alert to emergency – issues with Metal content and Viscosity

- Trend history of numerous factors including Metal, Viscosity, Additive depletion and Precursor to anticipate upcoming issues and do the preventive maintenance before there is an unforeseen catastrophic event.

We also recommend best storage practices to ensure that you have the proper storage room configured in the proper manner with racks etc., as well as proper and clean equipment and practices to refill equipment or do a change over.

We train your staff in the best lubrication practices and give them a comprehensive understanding of the function of lubrication and how proper lubrication can save your company thousands of dollars and keep your facility running reliably. Once you establish your Lubrication Champion we continue supporting you with close communications to update him on any advances in lubrication

We will propose a colour coding and naming system to minimize the possibility of using the wrong lubricants in the wrong places.